ÎÊÐäÒ * 1 – 0.25

ÒÓ Ó 27.3-00214534-095:2017 |

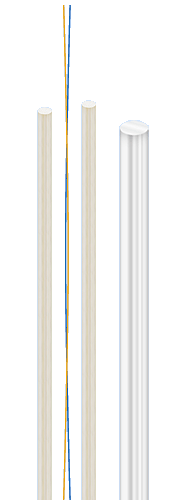

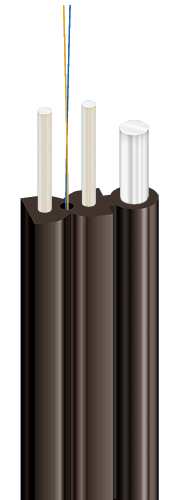

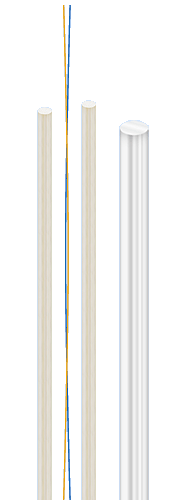

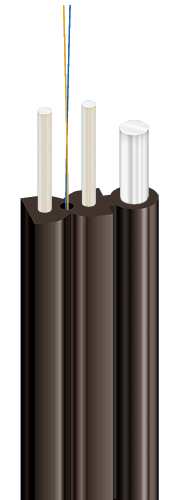

| Distribution fiber-optic cables with a fiberglass strength element, with an outer sheath of flame retardant polymer compound and external steel strength element |

| Mark formation: |

| ÎÊÐäÒ -[b] [c]1(1x[e])-0.25 |

| [b] quantity of optical fibers in the cable, possible values |

| • 1, 2 |

| [c] type of optical fiber |

| • A – single-mode with extended wavelength band (ITU-T G.652D, ITU-T G.657A1) |

| • D - single-mode, not sensitive to losses on macro-bending (ITU-T G.657A2) |

| [e] quantity of optical fibers in the module: |

| • 1 ... 2 |

|

|

|

| Manufacturing of cables with armouring (aramid yarns and/or corrugated steel tape) is possible |

|

|

|

| Order placing: sample of indication (corresponds to configuration pattern) |

| ÎÊÐäÒ-2A1(1x2)-0.25 • ÒÓ Ó 27.3-00214534-095:2017 |

|

|

|

| Cables are used for: |

| • in areas with exclusive fire safety requirements |

| • for laying between supports, inside and between buildings |

| • for laying between the main line and the building |

| • for laying in places with effect of high electromagnetic field |

|

|

|

| Cables are available in either gel-filled or dry construction |

| The color of the optical fibers of the cable can be optional |

| Cable length marking on cable sheath is possible |

|

|

|

| Fire safety code in accordance with ÄÑÒÓ 4809:2007: ÏÁ103122000 |

| Products of this mark meet the requirements: |

| • single wire cable flame retardance |

| • toxicity class Tk3 of the combustion products of nonmetallic elements (toxicity index over 120 g/m3) |

| • class ÄÒê1 on smoke-forming ability by smouldering of non-metallic elements (coefficient of smoke formation from 50 to 500 m2/kg) |

| • class ÄÏê2 on smoke-forming ability by combustion (minimum luminous flux more than 60 %) |

| • corrosive class Êê2 of combustion products of non-metallic elements (the number of halogen hydrides less than 150 mg/g, pH more than 4.3, specific conductivity less than 10 µS/mm) |