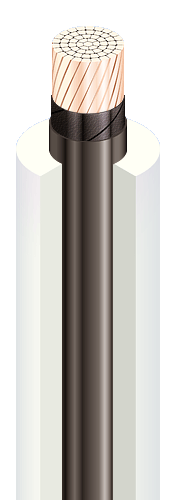

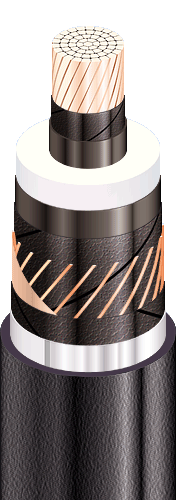

ÏâÝãàÏíã-132 1x1000

ÒÓ Ó 31.3-00214534-060:2011 |

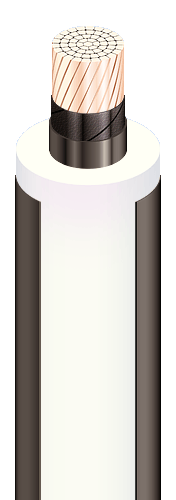

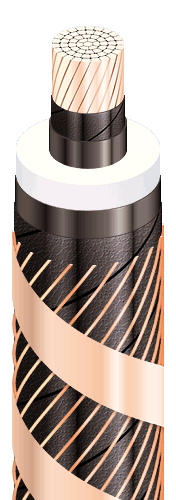

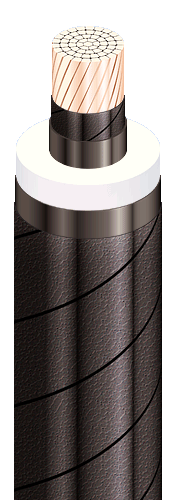

| Power cables with copper conductor, flame-retardant, with XLPE, longitudinal and transverse screen sealing and polymer compound outer sheath |

| For the cable of this mark correspond the foreign-made analogues: |

| HXCHBMK (FI) |

| Technical cable requirements correspond to IEC 60840 |

|

|

|

| Cables are used for laying: |

| • in premises, tunnels, ducts, mines, dry soil and outdoor under shelter |

| • single laying |

|

|

|

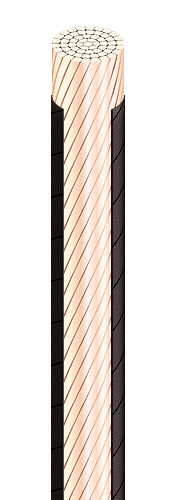

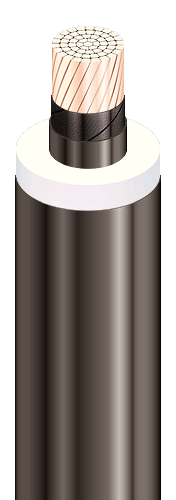

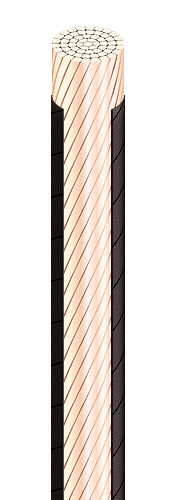

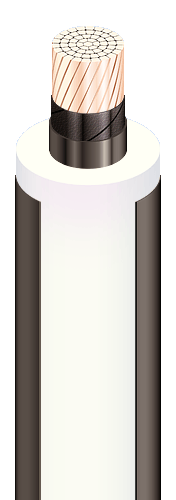

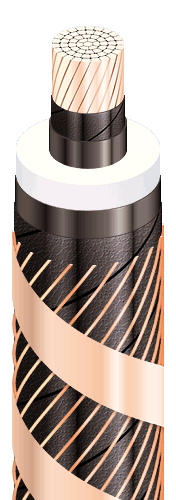

| It is possible to manufacture cable with a segmented conductor |

|

|

|

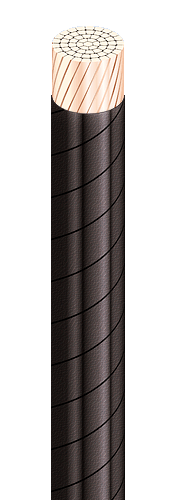

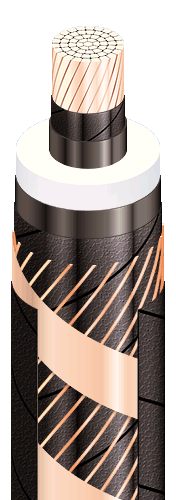

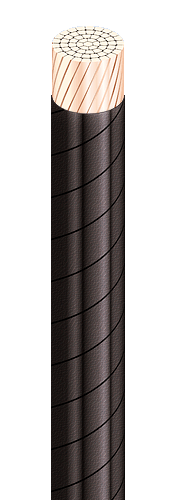

It is possible to manufacture cables with extruded semiconductor layer along outer sheath.

Order entry example: |

| ÏâÝãàÏíã-Ï–132 1x1000/95 ÒÓ Ó 31.3-00214534-060:2011 |

| An extruded semiconductor layer along outer sheath ensures the correct testing of cable line with sections of underground laying in polymer pipes. To learn more. |

|

|

|

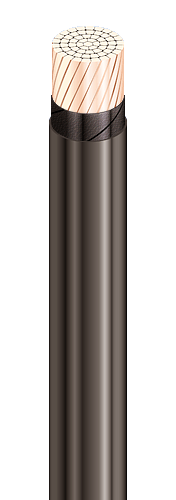

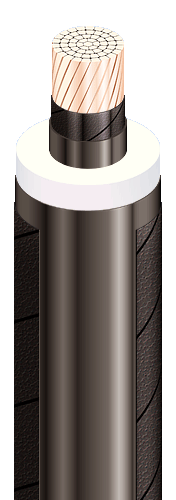

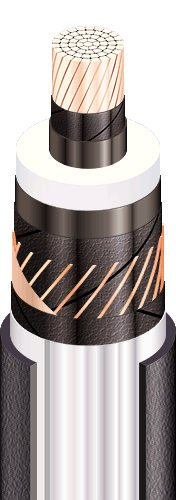

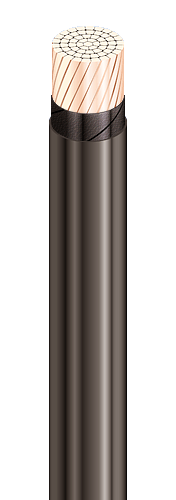

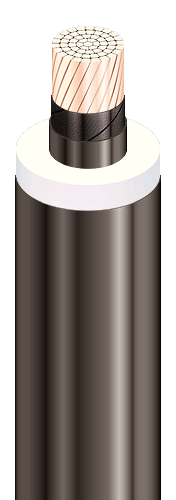

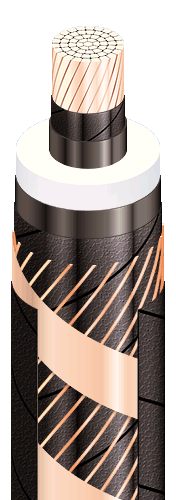

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÝãàÏíã-132 1x1000/95 (ÎÌ) ÒÓ Ó 31.3-00214534-060:2011 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

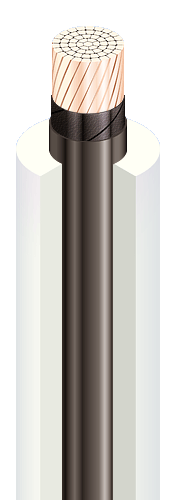

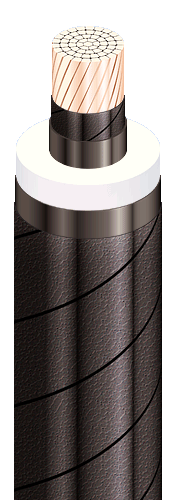

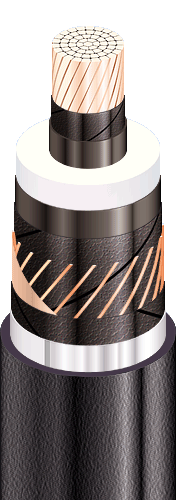

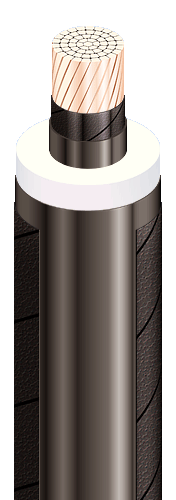

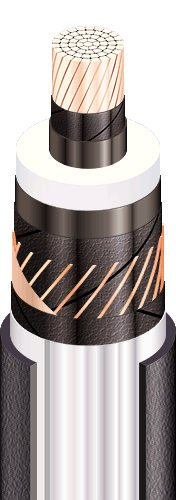

It is possible to manufacture cable with sealed conductor.

Order entry example: |

| ÏâÝãàÏíã-132 1x1000/95 (ã) ÒÓ Ó 31.3-00214534-060:2011 |

|

|

|

| Fire safety code in accordance with ÄÑÒÓ 4809:2007: ÏÁ121122000 |

| Products of this mark meet the requirements: |

| • single wire cable flame retardance |

| • bunched cable flame retardance category A |

| • toxicity class Tk1 of the combustion products of nonmetallic elements (toxicity index from 13 up to 40 g/m3) |

| • class ÄÒê1 on smoke-forming ability by smouldering of non-metallic elements (coefficient of smoke formation from 50 to 500 m2/kg) |

| • class ÄÏê2 on smoke-forming ability by combustion (minimum luminous flux more than 60 %) |

| • corrosive class Êê2 of combustion products of non-metallic elements (the number of halogen hydrides less than 150 mg/g, pH more than 4.3, specific conductivity less than 10 µS/mm) |