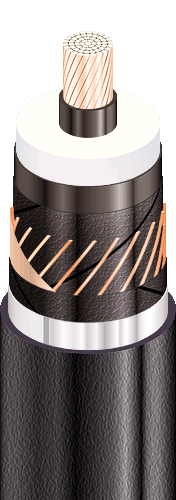

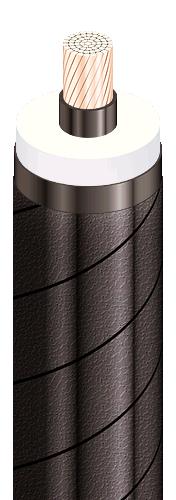

ÏâÝãàÏ-132 1x350

ÒÓ Ó 31.3-00214534-060:2011 |

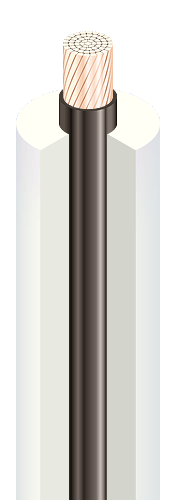

| Power cables with copper conductor, with XLPE, longitudinal and transverse screen sealing and polyethylene outer sheath |

| For the cable of this mark correspond the foreign-made analogues: |

| N2XS(FL)2Y (DE) • 2XS(FL)2Y (DE) • HXCHBMK (FI) • Cu/XLPE/CWS/LW/MDPE (GB) • XRUHKXS (PL) • ÏâÏ2ã (RU) |

| Technical cable requirements correspond to IEC 60840 |

|

|

|

| Cables are used for laying: |

| • in soil (trenches) |

| • in damp, partially flooded premises |

| • in ground with high humidity |

| • in non-navigable waters |

| • in the air, including cable structures, if provided the additional fire protection |

|

|

|

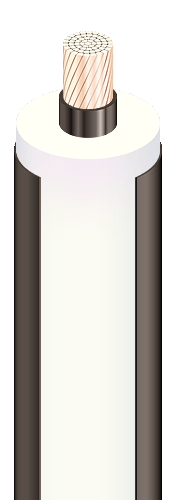

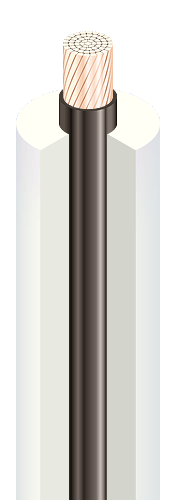

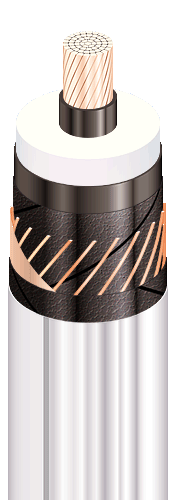

It is possible to manufacture cables with extruded semiconductor layer along outer sheath.

Order entry example: |

| ÏâÝãàÏ-Ï–132 1x350/95 ÒÓ Ó 31.3-00214534-060:2011 |

| An extruded semiconductor layer along outer sheath ensures the correct testing of cable line with sections of underground laying in polymer pipes. To learn more. |

|

|

|

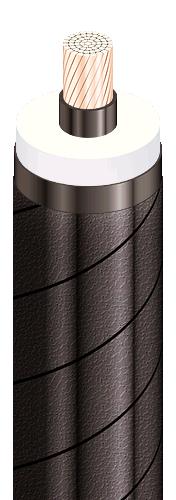

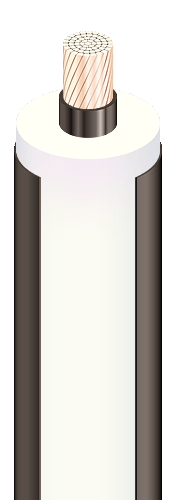

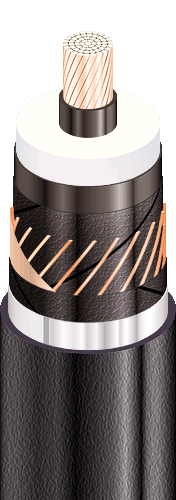

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÝãàÏ-132 1x350/95 (ÎÌ) ÒÓ Ó 31.3-00214534-060:2011 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

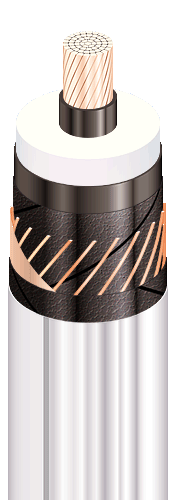

It is possible to manufacture cable with sealed conductor.

Order entry example: |

| ÏâÝãàÏ-132 1x350/95 (ã) ÒÓ Ó 31.3-00214534-060:2011 |

|

|

|