ÏâÅÀêÂíãä-30 1x1000

ÒÓ Ó 31.3-00214534-017-2003 |

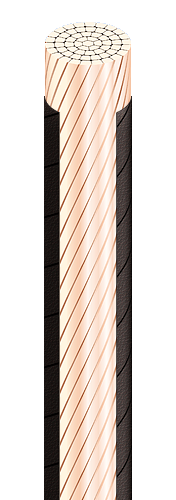

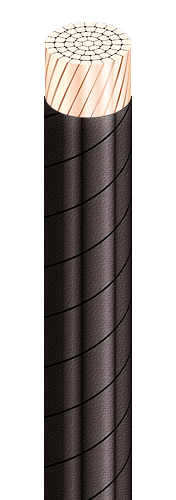

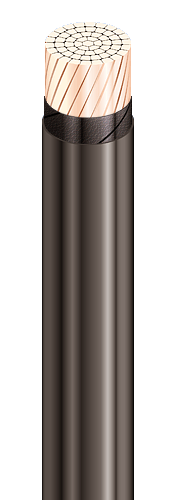

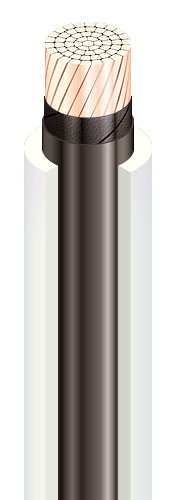

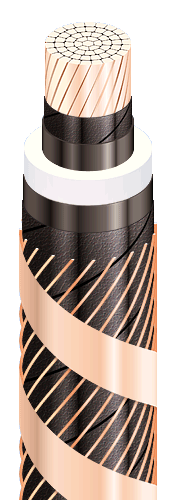

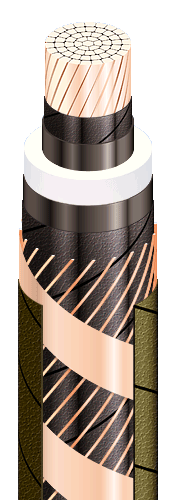

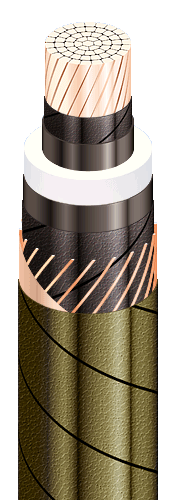

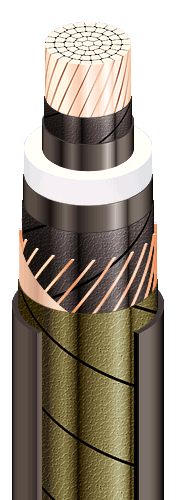

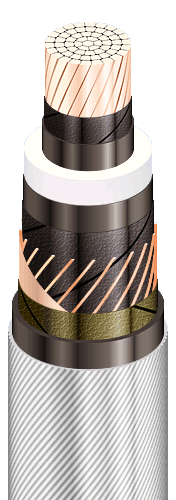

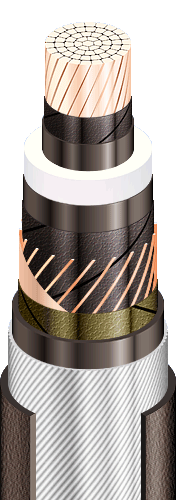

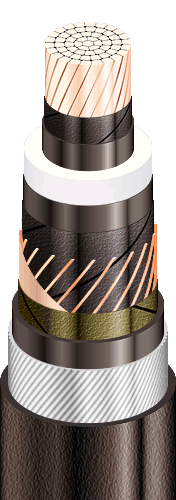

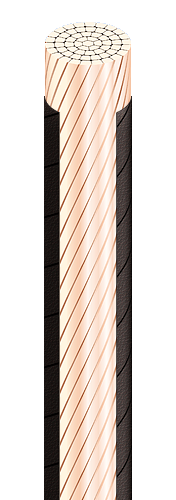

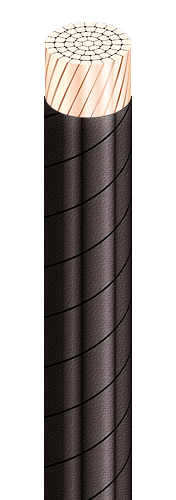

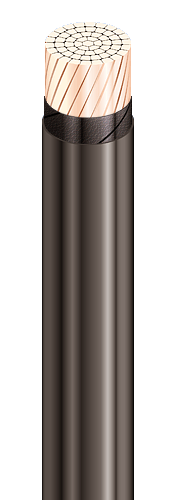

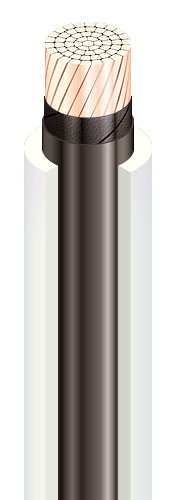

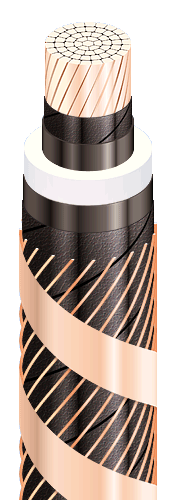

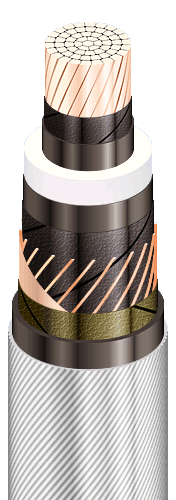

| SIngle-core power cables with copper conductor, flame-retardant, with XLPE, aluminium-wire armoured, with PVC compound outer sheath and with low smoke and gas emission |

| Due to non-magnetic armour, cables operate at AC |

| Technical cable requirements correspond to IEC 60502-2 |

|

|

|

| Cables are used for laying: |

| • in places, where small mechanical impacts on cable are possible, including tensile forces |

| • in premises, tunnels, ducts, mines, dry soil and outdoor under shelter |

| • in bunches |

| • at sites, where low smoke and gas emission are required (NPP, subway, large industrial facilities, high-rise buildings, etc.) |

|

|

|

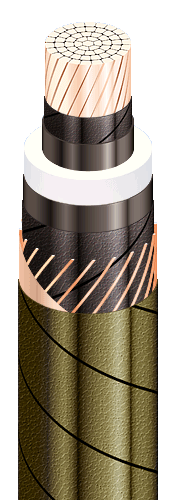

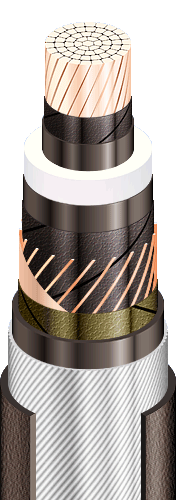

| It is possible to manufacture cable with a segmented conductor |

|

|

|

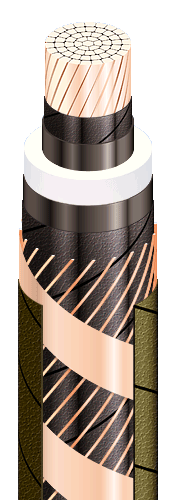

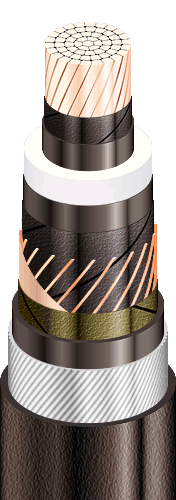

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÅÀêÂíãä-30 1x1000/70 (ÎÌ) ÒÓ Ó 31.3-00214534-017-2003 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

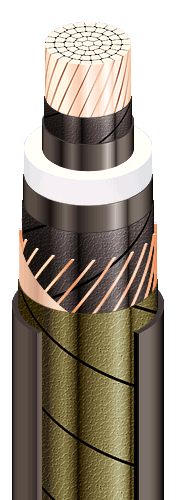

It is possible to manufacture cable with sealed conductor.

Order entry example: |

| ÏâÅÀêÂíãä-30 1x1000/70 (ã) ÒÓ Ó 31.3-00214534-017-2003 |

|

|

|

| Fire safety code in accordance with ÄÑÒÓ 4809:2007: ÏÁ122121000 |

| Products of this mark meet the requirements: |

| • single wire cable flame retardance |

| • bunched cable flame retardance category A |

| • toxicity class Tk2 of the combustion products of nonmetallic elements (toxicity index from 40 up to 120 g/m3) |

| • class ÄÒê1 on smoke-forming ability by smouldering of non-metallic elements (coefficient of smoke formation from 50 to 500 m2/kg) |

| • class ÄÏê2 on smoke-forming ability by combustion (minimum luminous flux more than 60 %) |

| • corrosive class Êê1 of combustion products of non-metallic elements (the number of halogen hydrides less than 150 mg/g, pH less than 4.3, specific conductivity more than 10 µS/mm) |