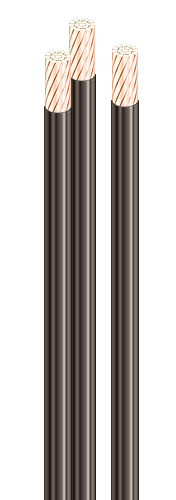

ÏâÝãÏíã-35 3x120

ÒÓ Ó 31.3-00214534-058:2007 |

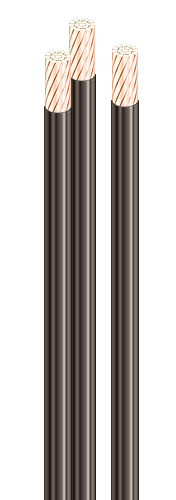

| Power cables with copper conductors, flame-retardant, with XLPE, longitudinal screen sealing and polymer compound outer sheath |

| Technical cable requirements correspond to IEC 60502-2 |

|

|

|

| Cables are used for laying: |

| • in premises, tunnels, ducts, mines, dry soil and outdoor under shelter |

| • single laying |

|

|

|

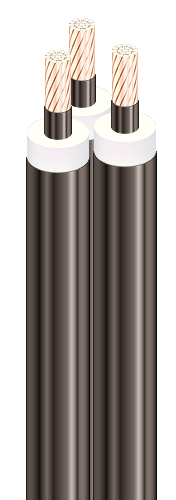

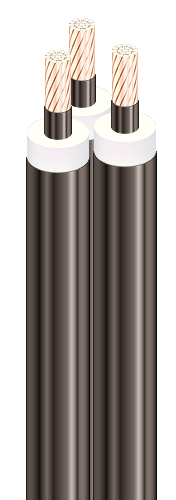

It is possible to manufacture cables with extruded semiconductor layer along outer sheath.

Order entry example: |

| ÏâÝãÏíã-Ï–35 3x120/16 ÒÓ Ó 31.3-00214534-058:2007 |

| An extruded semiconductor layer along outer sheath ensures the correct testing of cable line with sections of underground laying in polymer pipes. To learn more. |

|

|

|

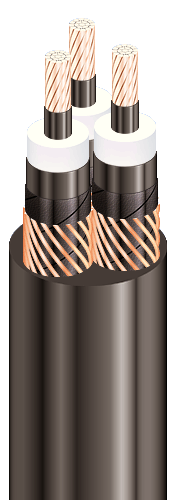

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÝãÏíã-35 3x120/16 (ÎÌ) ÒÓ Ó 31.3-00214534-058:2007 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

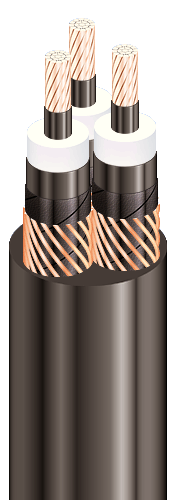

It is possible to manufacture cable with sealed conductors.

Order entry example: |

| ÏâÝãÏíã-35 3x120/16 (ã) ÒÓ Ó 31.3-00214534-058:2007 |

|

|

|

| It is possible manufacturing of cables in versions (A) and (B), flame-retardant when laying in bunches |

|

|

|

| Fire safety code in accordance with ÄÑÒÓ 4809:2007: ÏÁ101122000 |

| Products of this mark meet the requirements: |

| • single wire cable flame retardance |

| • toxicity class Tk1 of the combustion products of nonmetallic elements (toxicity index from 13 up to 40 g/m3) |

| • class ÄÒê1 on smoke-forming ability by smouldering of non-metallic elements (coefficient of smoke formation from 50 to 500 m2/kg) |

| • class ÄÏê2 on smoke-forming ability by combustion (minimum luminous flux more than 60 %) |

| • corrosive class Êê2 of combustion products of non-metallic elements (the number of halogen hydrides less than 150 mg/g, pH more than 4.3, specific conductivity less than 10 µS/mm) |