ÎÏÒ * 10 – 9

ÒÓ Ó 31.3-00214534-047:2005 |

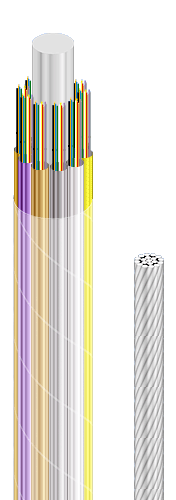

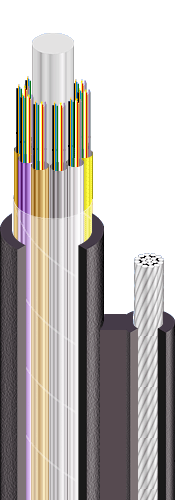

| Fiber optic overhead module-core cables, with polyethylene outer sheath |

| Mark formation: |

| ÎÏÒ-[a]-[b] [c]10(10x[e])-9 |

| [a] central strength element |

| • C – steel |

| • No marks – dielectric |

| [b] quantity of optical fibers in the cable, possible values |

| • 60, 80, 100, 120, 130, 140, 150, 160 |

| [c] type of optical fiber |

| • E – single-mode (ITU-T G.652B) |

| • A – single-mode with extended wavelength band (ITU-T G.652D, ITU-T G.657A1) |

| • C – single-mode with non-zero shifted dispersion (ITU-T G.655) |

| • M – multimode with core and sheath diameter ratio 50 : 125 mm (ITU-T G.651) |

| • B – multimode with core and sheath diameter ratio 62.5 : 125 mm (IEC 60793-2) |

| [e] quantity of optical fibers in the module: |

| • 1 ... 16 |

|

|

|

| Manufacturing of cables in climate version F is possible |

| Manufacturing of cables with steel strength element is possible |

| Manufacturing of cables with armouring (aramid yarns and/or corrugated steel tape) is possible |

| Manufacturing of cables with steel or dielectric wire rope (glass fiber rod) is possible |

| Manufacturing of cables with flame-retardant polymer compound outer sheath is possible |

| It is possible to manufacture cables with gel-filled core or dry core (with water-blocking yarns and tapes) |

| It is possible to manufacture cables with a number of core elements up to and including 18 |

|

|

|

| Order placing: sample of indication (corresponds to configuration pattern) |

| ÎÏÒ-100A10(10x10)-9 • ÒÓ Ó 31.3-00214534-047:2005 |

|

|

|

| Cables are used for: |

| • suspensions and operation at supports of aerial contact-lines, urban electric transport and aerial power transmission lines under impact of wind, ice or their combination loads |