Îà2ÊÏ * 5 – 20

ÒÓ Ó 31.3-00214534-036-2004 |

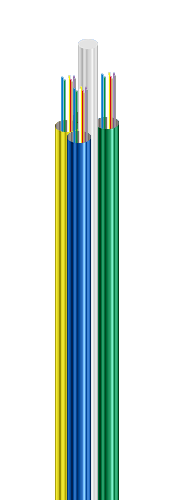

| Fiber optic module-core cables, double-layer galvanized steel-wire armoured, sealed with alumopolymer tape, with polyethylene outer sheath |

| Mark formation: |

| Îà2ÊÏ-[a]-[b] [c]5([d]x[e]+[f])-20 |

| [a] central strength element |

| • C – steel |

| • No marks – dielectric |

| [b] quantity of optical fibers in the cable, possible values |

| • 10, 16, 18, 20, 26, 28, 30, 32, 36, 40, 65, 70, 75, 80 |

| [c] type of optical fiber |

| • E – single-mode (ITU-T G.652B) |

| • A – single-mode with extended wavelength band (ITU-T G.652D, ITU-T G.657A1) |

| • C – single-mode with non-zero shifted dispersion (ITU-T G.655) |

| • M – multimode with core and sheath diameter ratio 50 : 125 mm (ITU-T G.651) |

| • B – multimode with core and sheath diameter ratio 62.5 : 125 mm (IEC 60793-2) |

| [d] 3 ... 5 – number of optical modules in cable |

| [e] quantity of optical fibers in the module: |

| • 1 ... 16 |

| (f) quantity of insulated copper conductors in cable |

| Optical modules are completed with string fillers up to total number of core elements |

|

|

|

| Manufacturing of cables with two copper insulated remote power conductors instead of two string fillers is possible |

| Manufacturing of cables in climate version F is possible |

| Manufacturing of cables with steel strength element is possible |

| Manufacturing of cables with polyethylene intermediate sheath between armour layers is possible |

| It is possible to manufacture cables with gel-filled core or dry core (with water-blocking yarns and tapes) |

| It is possible to manufacture cables with a number of core elements up to and including 18 |

|

|

|

| Order placing: sample of indication (corresponds to configuration pattern) |

| Îà2ÊÏ-32A5(4x8)-20 • ÒÓ Ó 31.3-00214534-036-2004 |

|

|

|

| Cables are used for: |

| • laying in soils of all categories, areas with soils subjected to cryosolic distortions |

| • laying on the bottom of navigable rivers and deep water canals (depth up to 100 m) |