ÎÀðÁãÏ * 5 – 2.7

ÒÓ Ó 31.3-00214534-036-2004 |

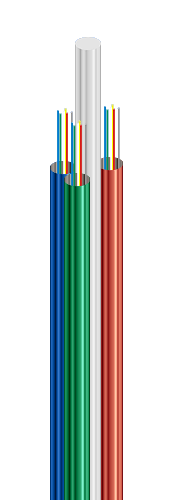

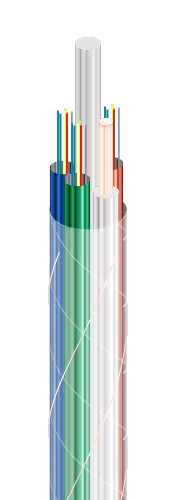

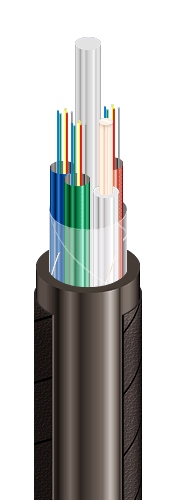

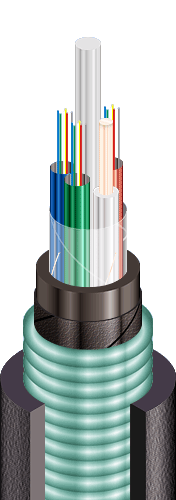

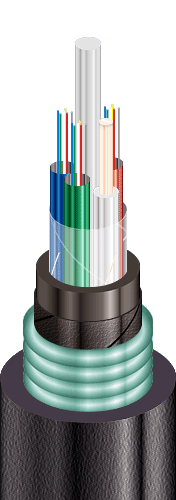

| Fiber optic module-core cables, aramid-yarn armoured, corrugated steel-tape armoured, with polyethylene outer sheath |

| Mark formation: |

| ÎÀðÁãÏ-[a]-[b] [c]5([d]x[e]+[f])-2.7 |

| [a] central strength element |

| • C – steel |

| • No marks – dielectric |

| [b] quantity of optical fibers in the cable, possible values |

| • 12, 14, 16, 18, 20, 24, 26, 28, 30, 32, 36, 40, 48, 60, 65, 70, 75, 80 |

| [c] type of optical fiber |

| • E – single-mode (ITU-T G.652B) |

| • A – single-mode with extended wavelength band (ITU-T G.652D, ITU-T G.657A1) |

| • C – single-mode with non-zero shifted dispersion (ITU-T G.655) |

| • M – multimode with core and sheath diameter ratio 50 : 125 mm (ITU-T G.651) |

| • B – multimode with core and sheath diameter ratio 62.5 : 125 mm (IEC 60793-2) |

| [d] 3 ... 5 – number of optical modules in cable |

| [e] quantity of optical fibers in the module: |

| • 1 ... 16 |

| (f) quantity of insulated copper conductors in cable |

| Optical modules are completed with string fillers up to total number of core elements |

|

|

|

| Manufacturing of cables with two copper insulated remote power conductors instead of two string fillers is possible |

| Manufacturing of cables in climate version F is possible |

| Manufacturing of cables with steel strength element is possible |

| It is possible to manufacture cables with gel-filled core or dry core (with water-blocking yarns and tapes) |

| It is possible to manufacture cables with a number of core elements up to and including 18 |

|

|

|

| Order placing: sample of indication (corresponds to configuration pattern) |

| ÎÀðÁãÏ-18A5(3x6+2)-2.7 • ÒÓ Ó 31.3-00214534-036-2004 |

|

|

|

| Cables are used for: |

| • laying in soils of all groups, including soils with low, medium and high corrosion activity, and in the areas contaminated by rodents, except for soils subjected to cryosolic and other distortions, as well as in cable ducts, blocks, etc. |