ÎÁãÏíî * 8 – 2.7

ÒÓ Ó 31.3-00214534-050:2005 |

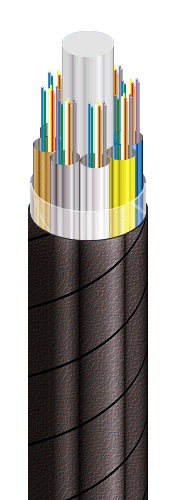

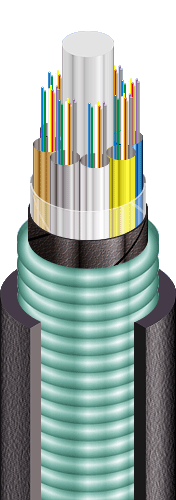

| Fiber optic module-core cables, corrugated steel-tape armoured, with polymer compound flame-retardant outer sheath |

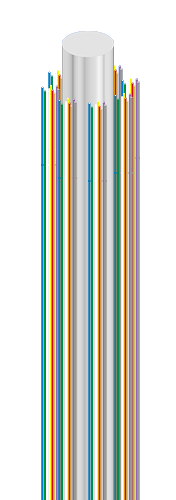

| Mark formation: |

| ÎÁãÏíî-[a]-[b] [c]8(8x[e])-2.7 |

| [a] central strength element |

| • C – steel |

| • No marks – dielectric |

| [b] quantity of optical fibers in the cable, possible values |

| • 32, 48, 64, 80, 96, 104, 112, 120, 128 |

| [c] type of optical fiber |

| • E – single-mode (ITU-T G.652B) |

| • A – single-mode with extended wavelength band (ITU-T G.652D, ITU-T G.657A1) |

| • C – single-mode with non-zero shifted dispersion (ITU-T G.655) |

| • M – multimode with core and sheath diameter ratio 50 : 125 mm (ITU-T G.651) |

| • B – multimode with core and sheath diameter ratio 62.5 : 125 mm (IEC 60793-2) |

| [e] quantity of optical fibers in the module: |

| • 1 ... 16 |

|

|

|

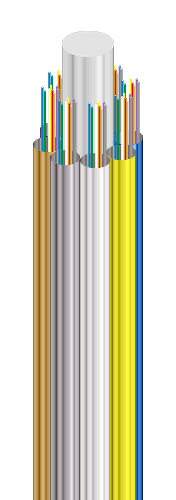

| Manufacturing of cables in climate version F is possible |

| Manufacturing of cables with steel strength element is possible |

| It is possible to manufacture cables with gel-filled core or dry core (with water-blocking yarns and tapes) |

| It is possible to manufacture cables with a number of core elements up to and including 18 |

|

|

|

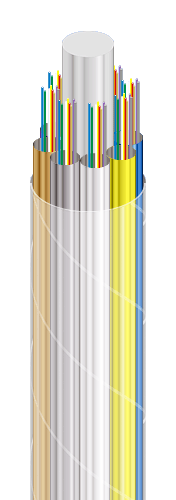

| Order placing: sample of indication (corresponds to configuration pattern) |

| ÎÁãÏíî-64A8(8x8)-2.7 • ÒÓ Ó 31.3-00214534-050:2005 |

|

|

|

| Cables are used for: |

| • installation in pipes (including air installation method), blocks, collectors at risk of damage by rodents |

| • in areas with exclusive fire safety requirements |

|

|

|

| Fire safety code in accordance with ÄÑÒÓ 4809:2007: ÏÁ130122000 |

| Products of this mark meet the requirements: |

| • single wire cable flame retardance |

| • bunched cable flame retardance category B |

| • class ÄÒê1 on smoke-forming ability by smouldering of non-metallic elements (coefficient of smoke formation from 50 to 500 m2/kg) |

| • class ÄÏê2 on smoke-forming ability by combustion (minimum luminous flux more than 60 %) |

| • corrosive class Êê2 of combustion products of non-metallic elements (the number of halogen hydrides less than 150 mg/g, pH more than 4.3, specific conductivity less than 10 µS/mm) |