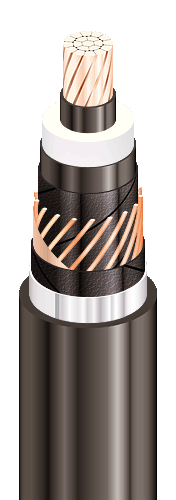

ÏâÝãàÀêÏó-15 1x120

ÒÓ Ó 31.3-00214534-017-2003 |

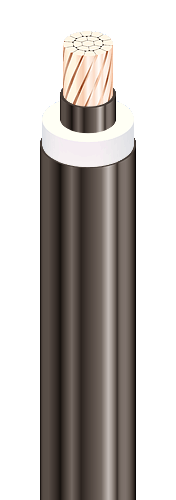

| SIngle-core power cables with copper conductor, with XLPE, aluminium-wire armoured, with longitudinal and transverse screen sealing, with strengthened outer polyethylene sheath |

| Due to non-magnetic armour, cables operate at AC |

| Technical cable requirements correspond to IEC 60502-2 |

|

|

|

| Cables are used for laying: |

| • in places, where small mechanical impacts on cable are possible, including tensile forces |

| • in soil (trenches) |

| • in damp, partially flooded premises |

| • in ground with high humidity |

| • in non-navigable waters |

| • on difficult route sections, according to the unique specification |

| • in the air, including cable structures, if provided the additional fire protection |

|

|

|

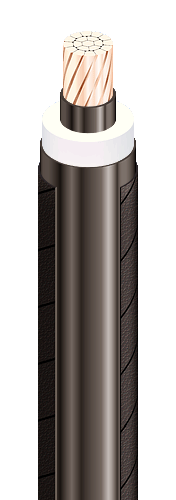

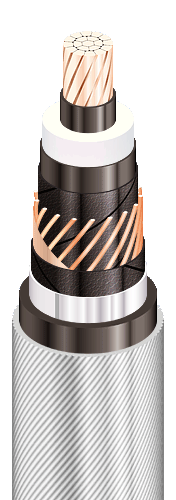

It is possible to manufacture cables with extruded semiconductor layer along outer sheath.

Order entry example: |

| ÏâÝãàÀêÏó-Ï–15 1x120/16 ÒÓ Ó 31.3-00214534-017-2003 |

| An extruded semiconductor layer along outer sheath ensures the correct testing of cable line with sections of underground laying in polymer pipes. To learn more. |

|

|

|

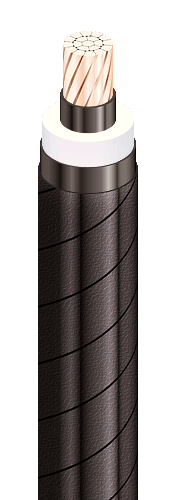

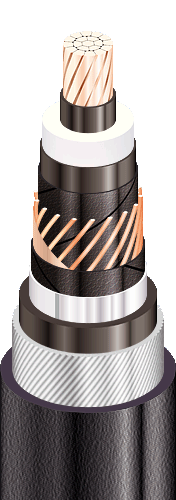

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÝãàÀêÏó-15 1x120/16 (ÎÌ) ÒÓ Ó 31.3-00214534-017-2003 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

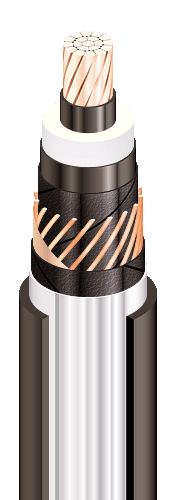

It is possible to manufacture cable with sealed conductor.

Order entry example: |

| ÏâÝãàÀêÏó-15 1x120/16 (ã) ÒÓ Ó 31.3-00214534-017-2003 |

|

|

|